Sigma-Nip records nip width, making older methods, such as carbon paper and embossed foils, obsolete.

Sensor Products has claimed the Sigma-Nip is faster, more cost effective, more accurate and more durable.

The product consists of a chain of sensor elements and Windows-based software. When placed between two contacting rollers, the sensors record and assimilate nip width readings on a laptop while it is being viewed.

Electrical engineer Mike Estelle, who works in Agfa Graphics' platemaking division, endorsed Sigma-Nip.

"In the past, we adjusted air pressure for nip but didn't have the feedback mechanism to ensure we were doing this precisely," Estelle said.

"Through Sigma-Nip, we have established a baseline for our rollers and we will use Sigma-Nip frequently throughout our plant."

Have your say in the Printweek Poll

Related stories

Latest comments

"'Support our ongoing growth? Growing in a declining market = more market share, and is last man standing strategy. That worked equally as well for Polestar...."

"Maybe now is the time for those publishers that rely on these guys to help them out for a change. No one left in the pub but the brawler who's knocked everyone out and now can't get a..."

"Another sad day for the industry, only made worse after reading that Ian Shenton is heading up the rescue bid... This guy has had more failed takeovers than Santa has reindeers. Just search on..."

Up next...

Investor exit 'not unexpected'

Walstead Group being put up for sale

Replaces the Pro C5300 series

Ricoh enhances usability and print quality with new range

Impressed with quality

Kall Kwik WGC boosts capabilities with new Revoria

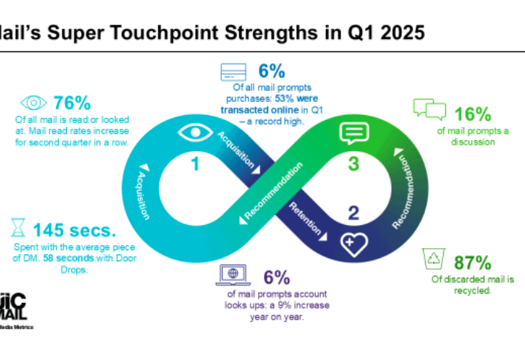

Volumes on JICMail’s panel increased by 5%