Running from 24-27 February at Messe Lucerne, the event attracted 120 exhibitors – 20 more than the previous outing in 2023 – and 6,800 visitors – up by 100 on 2023, who spent an average of 2.3 days at the show each.

It had a slightly different feel to usual. Where it has traditionally specialised in continuous- feed inkjet – indeed, it used to focus on monochrome transactional print and low-level direct mail – this year the event added additional technologies to the mix – including more sheetfed printers than ever before, and there were more commercial jobs running live than previously.

This was partly facilitated by the increased space available to exhibitors, as catering was moved from its traditional spot at the back of Hall 1 to the previously unused Hall 3.

With many of the major printer manufacturers taking larger, premium stands now that the option was available, and being able to decorate them with branding, graphics, and print samples, the show had a less egalitarian feel than in years past but it was easier to get onto the stands of some of the big players who previously had high footfall but a smaller space at the show.

Philipp Fritschi, head of communications and projects at Hunkeler, said the show was “the most successful in its history”.

“We are very satisfied with a 20% increase in exhibitors and visitors. We, as well as most of the exhibitors, were able to record many successful sales. Organisationally, the trade fair ran smoothly, our small team was challenged but happy. The chosen slogan, ‘Connect’, was very appropriate and fitted in very well with the current times.

“With the new, larger stand layouts for large exhibitors, we were able to create more space. This meant that more complex and connected solutions could be shown. Sheet finishing was also presented to a greater extent. Be it with additional high-performance large-format printers or with finishing solutions.”

Fritschi added the key to the event’s success “probably lies in the fact that there are fewer and fewer comparable events”.

“Nowhere else can you find so many solutions in such a compact space. Real solutions, installed from A to Z, with practice-orientated workflows that produce end products across all partners. Focused on product and advice – without a lot of promotional attention on site.”

While the presses on show in Lucerne – in terms of print quality, speeds, press drying systems that are helping to facilitate this high quality at very high speed, the capability to handle a wider range of materials, and automation – have clearly continued to improve since the 2023 event, there was also a lot of buzz around the perimeter of the halls, where software and workflow companies could be found.

Many analysts felt that it was in these areas where a lot of the time-saving efficiencies in inkjet are currently coming from.

“The most important trends were clearly connectivity. Networked solutions – automated processes with all the necessary pieces of the puzzle required for an entire production chain,” said Fritschi.

“The first trends for processing B2 sheets in high-performance digital printing were also on display. We are very excited to see how the market will continue to develop. Basically, the inkjet systems have become even more powerful in terms of print quality and speed.”

He added: “We are seeing strong interest in the commercial print sector. Highly flexible solutions are in demand here, format variability but also handling from light to heavyweight paper.

“With our Gen8 Evo solution, we optimally support operators with demanding production requirements. There will certainly be a lot more happening on the market in the next two years.

“We see further requirements in the networking of systems and processes. Solutions should increasingly take over entire process chains as automatically as possible. A lot will be going on in the near future. But keep in mind: the future belongs to those who connect.”

AI, the dominant trend of the last couple of years, also had a far bigger presence than ever before, not just in the way press manufacturers are harnessing its capabilities for things like predictive maintenance, but also new AI apps that have been developed to help users.

OFS, a first-time exhibitor that has a cloud-based software, was showing off its newly launched AI technology called Mayvn. OFS partners with companies who want to improve their operational efficiencies, and offers users live real-time data, operator feedback and analytics.

Its technology helps users to reduce setup times, unplanned downtime, short stops, run slow periods, and waste, while increasing operator engagement, production speeds, output, and profit.

Jonathan Newton, general manager, Europe, said: “We think we’ve got a world first, game-changing solution. If the internet brought us information, AI is going to bring us the answers. AI adoption in print manufacturers is far behind other markets, but senior leaders want to invest more in AI, and they want to be a bit more mature when it comes to AI to help drive their business, whether that’s workflow, operations quality, or efficiency.

“The AI we’ve developed is a very simple chat box where you can ask any question: e.g. ‘tell me how my factory did yesterday’ or ‘I’ve got a million dollars to spend – where should I spend it in my business?’.

“Everybody who uses it is absolutely in awe of what it can do, because it puts a data scientist in everybody’s pocket. Everybody suddenly has an ability to interrogate data, to find observations, to become an expert in a particular area of their business.”

With connectivity dominant in Lucerne, Karl Ciz, co-founder of fellow first-time exhibitor CoCoCo, was showing off its new ‘All You Can Integrate’ pricing model for its vendor-agnostic connectivity platform.

“Automation can only happen if there’s good connectivity. I think everybody in this room has their own cloud and their own internal software suites, but the average print house probably has five of those vendors, each with a cloud, each with an API and so on, and has to knit them together, and that burden has always fallen with the printer themselves.”

He added: “What we’re saying, to even those vendors, is that we can provide an integration player for you with the outside world.

“So we gather all of those APIs and say to the end user that they don’t need to integrate all of this stuff anymore. We’ve now got all of these integrations and we give you the platform – we bridge into your internal network that gives you full access to anybody that we’re integrated with.”

Despite the sector advances, and the claim by multiple press vendors at Hunkeler that the difference in the quality of print produced by offset and inkjet presses is now practically comparable, there is still vast potential for further inkjet market penetration.

But there are signs that more print companies are now thinking about inkjet as an alternative to either – or both – offset, and toner-based digital.

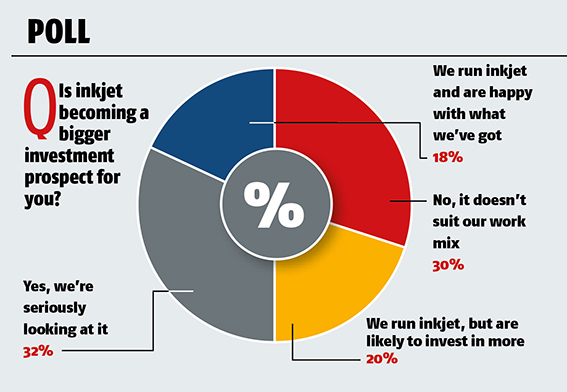

A recent Printweek poll that asked, ‘Is inkjet becoming a bigger investment prospect for you?’ found that while just under a third (30% – down from 33% in 2023) said it did not suit their work mix, the remainder were either now seriously looking at it (32% – up from 24% in 2023), or already running inkjet and likely to invest in more (20%) or happy with what they’ve got (18%).

Fujifilm Europe was demonstrating the Jet Press 1160CFG, its first foray into the continuous-feed market in Europe. Business development manager Mark Stephenson said: “It’s probably been at least 10, if not 15 years, that people have looked at continuous-feed inkjet presses and said, ‘hey, you could do commercial work on this’.

“But what we found is that you can’t take something that was built for a different market and just drop it in there, you need to have a different approach. That’s why we’ve got CFG – G stands for graphics. And we’ve got this extra unit on the front of the CFG called the Paper Stabilizer.”

This unit, which Stephenson described as “so logical and so simple”, regulates the moisture content of paper before printing starts.

Visitors and exhibitors are already highly anticipating the next Hunkeler Innovationdays – scheduled from 22-25 February 2027 in Lucerne – and it’s little surprise with the way its core markets are continuing to grow.

“I saw a study, from IDC I think, which predicted that the digital volume year-over-year in the next five to seven years will kind of double against what it is now,” said Eef de Ridder, vice president at Ricoh Europe Graphic Communications.

“But the majority of that growth will come from inkjet, where toner will still stay quite stable – and stable at a very good level, because it’s a very healthy business for us and for our colleagues in the market.”

He concluded: “But high-speed inkjet is where the big growth for the future will be, and where we will also put a lot of our dollars on research and development.”

OPINION

German Sacristan, group director digital printing production services, Keypoint Intelligence

German Sacristan, group director digital printing production services, Keypoint Intelligence

Hunkeler Innovationdays wrapped up in Lucerne, Switzerland, reinforcing its evolution into a full-fledged yet guest-centric trade show. With ‘Connect’ as its theme, the event showcased how people, solutions, and processes integrate for seamless production.

The show featured 13 major digital press manufacturers alongside finishing, software and paper vendors. Workflow automation stood out, with vendors nearly doubling from 15 to 27, highlighting the growing need for connectivity and data-driven efficiency in print.

While major press launches were limited, roll-fed inkjet advancements took centre stage. HP, Canon, Fujifilm, Ricoh, Kodak, and Screen focused on quality, productivity, costs and sustainability – now a key factor in print buyers’ decisions (more details overleaf).

Software steals the show: workflow automation emerged as a game-changer. Vendors showcased seamless software-to-hardware connectivity, reinforcing the industry’s shift toward fully integrated, data-driven production.

Standout software innovations: CoCoCo’s ‘All You Can Integrate’ pricing disrupts traditional licensing models; Dataline’s MIS/ERP system offers 80-plus integrations for intuitive workflow management; Enfocus Switch simplifies automation via an app store model.

OneVision’s Automation Suite tailors automation to unique business needs; and SpencerMetrics delivers real-time analytics for business insights.

Hunkeler Innovationdays 2025 showcased the convergence of hardware, software, and automation, helping print service providers balance speed, cost, and sustainability. As AI, cloud adoption, and workflow integration accelerate, print production is moving toward seamless, end-to-end efficiency – making this event a must for those looking to stay ahead.

On the stands at Hunkeler Innovationdays 2025

Canon celebrated 10 years in production sheetfed inkjet. It showed the ProStream 2133 webfed inkjet press printing at up to 133m/min while the VarioPrint iX3200 B3 sheetfed inkjet press made its show debut in its inline configuration with a Horizon iCE StitchLiner Mark V. Senior director of marketing and innovation for production printing at Canon Europe, Jennifer Kolloczek, said: “In the last two years, we have announced many new additions to our portfolio. The end-to-end solutions to those full production lines, and workflow as a part of those, has become more and more important to be able to analyse together with interested parties about what they need, where they are today, and maybe to look at the next 10 years and challenge ourselves on where we want to be then, and see things as steps on the way. Right now, it’s all about enabling people to do more with digital print.”

CP Bourg showed its new Bourg Booklet Maker (BBM) 40/60+, which demonstrated its ability to make booklets from one single sheet of paper up to 60-plus sheets or corner, head, and side stitch documents up to 60-plus sheets, utilising two or four stiches, plus square edge the finished booklets.

Fujifilm showed the Jet Press 1160CFG. This machine features the newly developed Paper Stabilizer, which seeks to solve issues found in high-speed inkjet printing by regulating the moisture content of paper before printing starts, improving production efficiency, print and finishing quality.

Heidelberg, which was sharing a booth with Muller Martini, handed a world premiere to a new nearline post-press system, the Stahlfolder TH 56/66 Fireline, while it also showcased the Jetfire 50 in its new livery.

HP demonstrated a full in-line book production workflow with its PageWide Advantage 2200 web inkjet press and Indigo 120K, while HP Indigo introduced its latest generation of consumable supplies designed to enhance print sustainability and boost productivity. “There is a lot of enthusiasm around the Indigo 120K; it has proven outcomes with 30% more productivity than the previous configuration, which is amazing,” said Noam Zilbershtain, vice president and general manager at HP Indigo. “And bringing our AI innovations to the 120K, and some of them also to the Indigo 18K, wowed our customers because they’re touching exactly the right points of operator skills, ease of use, and the productivity they are bringing.”

Hunkeler itself highlighted new innovations including the Gen8 Evo roll to stack, while also new to the show was the Starbook Sheetfolder with pallet feeder, which had its world premiere at Drupa 2024.

IBIS Integrated Bindery Systems unveiled the IBIS Smart Label-binder, a variant of the company’s existing Smart-binder, which has been optimised to produce ‘Extended Content’ labels (ECLs).

Insoft Automation premiered Imp version 14, its dynamic ganging, imposition and estimating software that is said to offer faster, smarter ganging and enhanced integration with third party MIS and improved post-press functionality. “We decided to focus on smaller shows. At Hunkeler it’s not like there are 200,000 visitors; you’ve got people who know exactly why they’re coming, and automation is a theme,” said Santosh Mulay, vice president – business development at Insoft Automation.

Kodak demonstrated the speed of its Prosper 7000 Turbo Press by printing excerpts from movie The Last Showgirl and music videos from Kesha and AntsLive that were shot on Kodak film to simulate the effect of a movie being projected. The movie sequences were printed with water-based Kodak Ektacolor inks at 410m/min. When printing the images, the Prosper 7000 achieved a frame rate that was high enough for the movies to be played back smoothly on the monitors of the machine’s quality monitoring system.

Mondi showed an expanded Nautilus recycled paper range as part of its portfolio of high-speed inkjet papers. The Nautilus ProCycle range is made from 100% post-consumer waste, and its sustainability certifications include Cradle to Cradle Certified Bronze, Blue Angel, FSC and EU Ecolabel.

Muller Martini, which acquired Hunkeler just over a year ago, presented three systems for smart factories that combined the strengths of different partners. One highlight was an inline application for producing softcover books from white signatures in different formats and thicknesses.

Ricoh showed its high-speed inkjet and sheetfed production portfolio, represented by the Pro VC80000, Pro VC40000, and Pro C9500 printers, as well as an interactive presentation of the Pro Z75 B2 inkjet press.

Riso was marking 20 years since its entry into inkjet printing. One of its innovations on show was ExpeJet, a fully automated printing and inserting system that combines Riso’s ComColor GL9730 inkjet printer with Pitney Bowes’ new Sirius production inserter.

Sappi brought its Magno Web portfolio to the event. The woodfree coated paper is now partially produced at the Kirkniemi Mill, where direct fossil greenhouse gas emissions have been reduced by 90%. Conor Evers, Sappi’s head of marketing operations, said: “Magno is suitable for all print technologies. It works on sheetfed, dry toner, and the Magno Web products particularly, work very well on high-speed inkjet. We’re super confident in the quality of it.”

Scodix showed off its new partnership with Winter & Company, which supplies high-quality cover materials for the publishing industry.

Screen Europe demonstrated its flagship Truepress Jet 560HDX, which illustrated the firm’s new Truepress SC2 Ink. The press produces high-resolution 1,200dpi output at up to 120m/min, without primers on offset-coated papers.