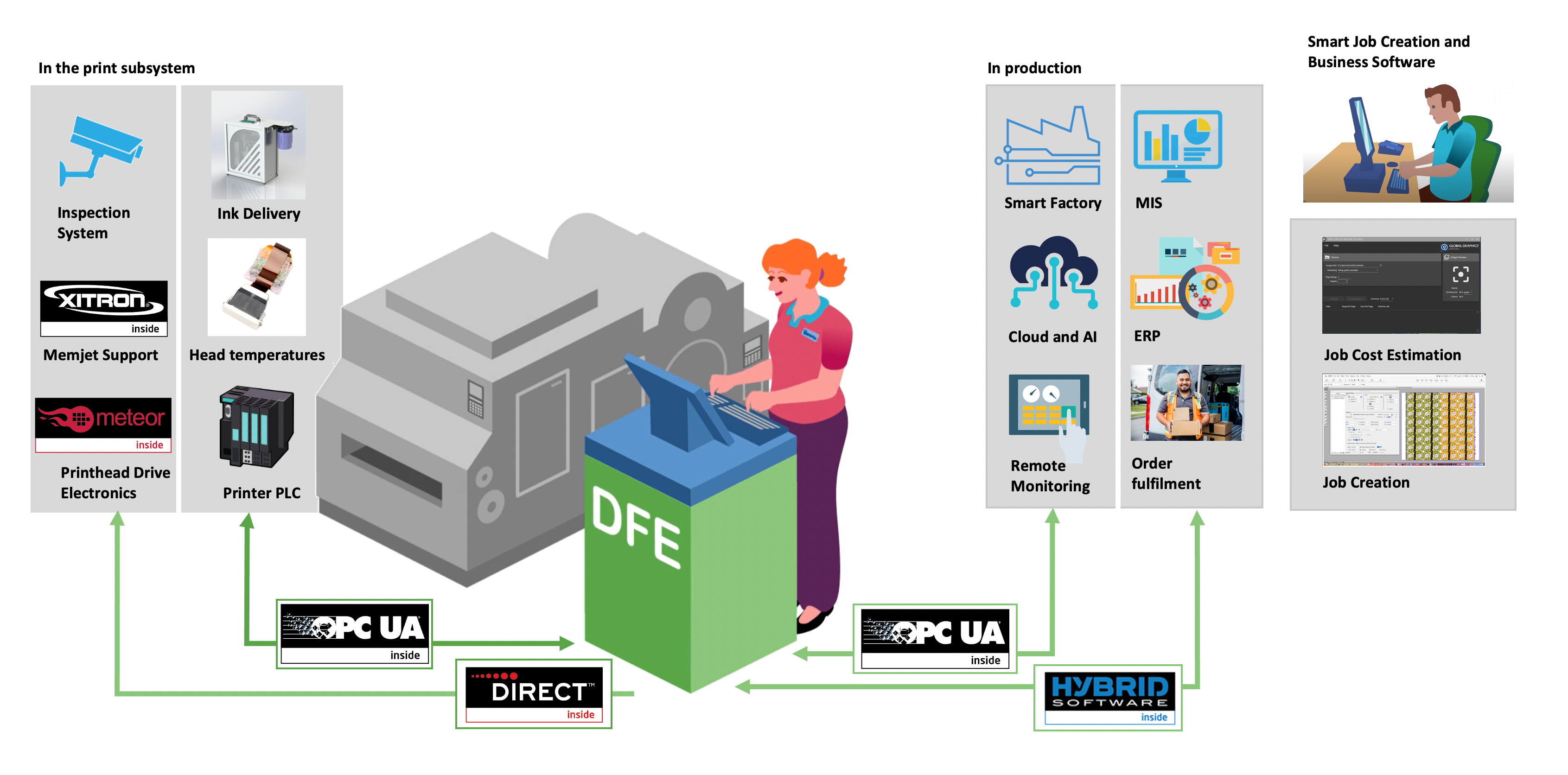

The Smart DFE brings together know-how from Global Graphics companies Hybrid Software, Meteor Inkjet and Xitron, as well as Global’s own software expertise.

The initial version is targeted at industrial label and packaging applications and spans a raft of functions including PDF creation, variable data printing, screening, image optimisation, ripping and data collection.

Nick de Roeck, chief technology officer at Global Graphics Group, said the business was “unique” in being a single supplier of all the necessary components.

“We are also in a perfect position to deliver this at a cost that allows mass customisation to be a commercial reality,” he said.

He said the initial focus on labels and packaging was because “no matter what customised products you produce, you will need to label and package it”.

“We will launch other Smart DFE variants in the coming months.”

The DFE is targeted at OEMs and is available immediately.

Global Graphics is focusing on applications for so-called automated or ‘industry 4.0 smart factories’.

New Smart DFE uses know-how from across the group's companies

Eric Worrall, vice president of products and services at Global Graphic Software, said SmartDFE could handle “any industrial production scenario”.

“It provides a complete single source software and electronics stack that does everything from job creation through to printheads. Our Artemis Print Operator AI builds print knowledge into the software to keep the workflow running at maximum speed and quality,” he stated.

Global Graphics also recently joined the OPC Foundation, which develops and maintains the Open Platform Communications industrial interoperability standard.

Worrall said that some existing customers had effectively built parts of the system themselves, “but not as fully integrated as what we now have”.

“There are people that are taking parts of the Smart DFE and using them in production at the moment, but not as this complete package. This is something we think is new.”

The Cambridge-headquartered firm also emphasised that all of the component parts involved in Smart DFE were still available separately.