"Since Drupa 2008, we have gone through a huge diversification," says chief executive Mark Handford. "Coming away from that show we decided that we could no longer just print B1 sheets."

The firm will have gone from novice to market leader in five years by the time Indigo 10000 number two arrives in August.

Handford sees having two machines as expedient for the type of work they lend themselves to: "If we hadn’t got redundancy we would shoot ourselves in the foot, especially for work with an overnight turnaround."

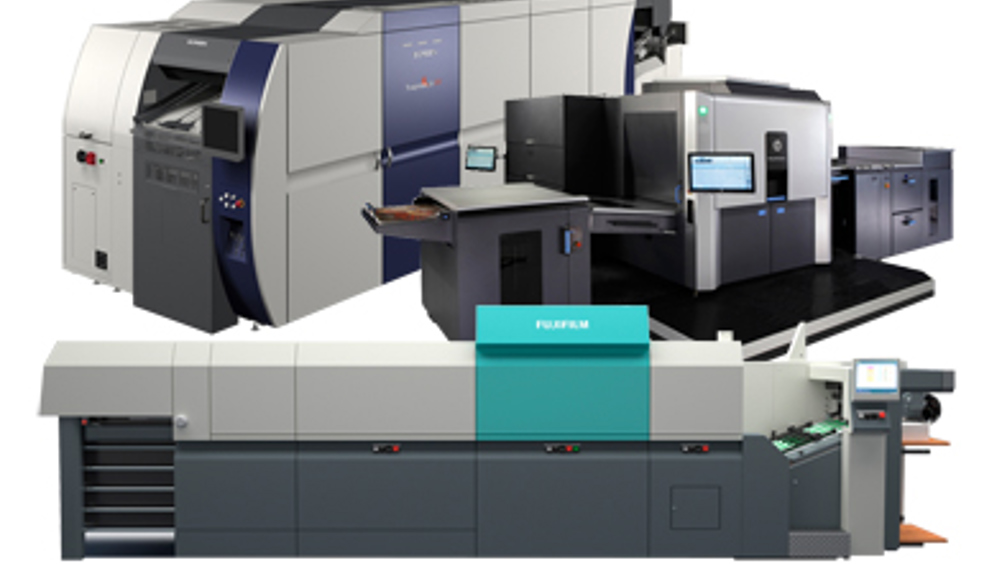

Precision Printing, the other UK beta site, is taking a more cautious approach and waiting to finish the beta before deciding whether to do the double. Commercial installations are about to begin, with MPG set to become the first in the UK later this month. Half a dozen 10000s are expected to be running in the UK by the end of the year. As for HP’s rivals, in the UK only RCS, with its Screen Truepress Jet SX, is also in the B2 digital club, while Fujifilm claims three JetPress installs across Europe.

Those figures fit with analyst projections. The InfoTrends Production Printing & Copying Forecast, published last May, expects 66 machines to be installed in Western Europe in 2013, up from seven in 2012. Although the number of installations is low, each press will be printing a lot. The firm estimates that, by 2016, B2 digital presses will be responsible for 4.4% of all digital colour pages produced in Western Europe. B2 digital vendors aren’t predicting a massive installed base but, like InfoTrends, expect each machine to produce a lot of pages.

"Because of the cost of entry I don’t expect there to be hundreds of B2 Indigos like there are B3s, but I do expect most B2 sites will have multiple machines," says HP Indigo and High Speed Inkjet Web Press UK country manager Nancy Janes, "I think B2 digital will be as common as the digital flatbed in wide-format. Five years ago, there were no HP FB7500s in the UK and there are now more than 50."

Predictions of the work that B2s will produce fall into three areas: taking volume from smaller format digital and B2 litho, and new markets.

Precision Printing, the other beta site is already finding the first of these areas to be the case.

"It is proving to be a great platform with lots of imposition efficiency," says Precision managing director Gary Peeling. "We are finding out that we can lay up five A4s or a 20pp A5 section on a sheet, which increases productivity by 25%. Because of the cost of digital, that makes a big difference."

As for the second area, the argument isn’t clear cut.

Ultra-short runs

Pureprint has migrated ultra-short runs of fewer than 50 copies from B2 litho to digital.

"It comes down to the cost and speed of B2 technology," says Paul Sherfield, managing director at consultancy Missing Horse. "An average B2 run is 1,800 sheets. The latest litho presses handle at least four of those per hour, whereas the digital presses only produce two."

How short a run will depend on how slick the litho operation is and the job mix.

Swindon’s doyenne of efficient sheetfed production, ESP Colour, which has recently dipped a toe into the digital water, is watching developments. Managing director Anthony Thirlby believes that, for all but the shortest runs, litho is still king.

"For static products I’m waiting to see the ROI," he says. "On a 250 run, I’ll confidently go against any digital device."

New applications will be key to the success of B2 digital presses. Precision was already heavily involved in personalised products and the larger format has opened up a raft of new photo products. RCS opted for the Truepress Jet SX because it is convinced that personalised gifting is going to be the next big thing.

"POS and packaging are new markets that the 10000 is opening up to us," says Pureprint’s Handford. "The press is a game changer. We are working on prototype and short-run packaging for luxury brands up to 5,000 pieces."

Personalised wrapping paper

He’s also been approached about personalised wrapping paper.

Pureprint’s experience highlights the chicken-and-egg nature of the situation.

"It will help our production platform, but I don’t think it will be critical," says ProCo sales and marketing director Jon Bailey, who has signed up to get a 10000 in the next year. "Once we have one, we will see what work fits and how it changes our production and business model."

Sherfield believes firms are taking a wait-and-see approach.

"Typically, successful printers are short-run colour specialists with B2 litho, SRA3 digital and wide-format print," he says. "I know of such firms who are keeping older B2 litho presses longer to see what happens."

For smaller firms, a mixed basket of jobs comprising B2 offset and B3 digital migration and new markets will be key to controlling cap-ex and cost-per-page, and generating sufficient utilisation to make B2 digital pay. That is a tall order for the first generation of B2 digital machines and the second generation may take more than a couple of years to arrive.

In the mean time, some vendors are offering bigger but not-quite-B2 digital machines, such as Kodak, MGI and Xerox, which all offer long-sheet SRA3 machines.

"The interest in B2 digital is a good thing, as clients are starting to design products that benefit from a larger-format sheet, although they don’t necessarily have to be B2," says MGI Technology UK director Chris Blanchard.

READER REACTION

Is the industry about to be revolutionised by B2 digital?

Jason Oliver, senior vice-president digital solutions, Heidelberg

Jason Oliver, senior vice-president digital solutions, Heidelberg"I’m not going to argue that there isn’t a market for B2 digital. It is a segment that we are working on. Our goal is a price that you can afford to pay the cost of the machine back. Customers say that Anicolor and the Linoprint C can cover most of what they want to do. It is important to realise how efficient offset is; with that, a high-priced digital offering is squeezed. How do you pay back a $1m machine when you can buy a high-quality digital press for a tenth of the price with a very competitive cost per page?"

Keith Dalton, managing director, Fujifilm UK

Keith Dalton, managing director, Fujifilm UK"Short run is where we see the demand, and short run is getting shorter. In B2 now, a long run is in the thousands; in the future it will be hundreds. B2 digital is a new technology and people have to get used to new business models. Purchase price of the kit is only one factor in the overall price of the print. Profitability is what people have to focus on. New products can unlock the customer’s approach to the market."

Bui Burke, vice-president, sales, Screen Europe

Bui Burke, vice-president, sales, Screen Europe"There are a lot of cynics about B2 digital, and it’s not a mass market machine but, for firms that have the right ideas and applications, it is possible to make a lot of money. It suits high-value work, such as gifting, that follows on from photo products and personalised greetings cards, and for which B2 is needed for boxes and wrapping paper. As consumables costs come down and speed increases, B2 digital will come into the remit of short run. But at the moment, the SX is not a replacement for the Speedmaster."

OPINION

Flexibility and quality of B2 digital make it a no-brainer

Francis Atterbury, Partner, Hurtwood Press

Francis Atterbury, Partner, Hurtwood PressB2 digital has opened up new opportunities for Hurtwood Press. I already believe that the HP Indigo produces higher quality on uncoated stock than litho, so we primarily use it for its quality. We have had work produced on the two beta test HP Indigo 10000s in the UK and every time a job comes back, the quality on these presses has got better.

Undoubtedly, for those who need to use digital print’s personalisation capabilities, the larger format is beneficial, but it is also an important development in the book market we serve, and that isn’t dependent on the ability to personalise or use variable data.

With B2 digital, I can print almost all our book formats as folding sections – that isn’t possible with the smaller digital presses. So I’m no longer restricted by the size of the sheet. Section sewing is the only way to make a high-quality book and, although the on-demand book world is set up for perfect- and PUR-single-leaf-bound books, all our books are sewn; meaning they open easily, lay flat and last forever. A B2 sheet makes this possible for all but the largest of our books.

While the bigger digital press on its own is good, once finishing equipment has been released to match bigger digital presses it will lead to more efficient production rather than just more efficient printing. What will be very interesting is when they put the finishing lines on the back of the press to offer inline folding. It will be a huge advantage if the press can deliver folded sections. Currently, the short run lengths we produce mean we need to fold by hand as it isn’t practical to set up a binder for such short runs.

At the same time that larger-format digital brings benefits, litho technology isn’t standing still in the face of this increased competition. Litho is getting more competitive all the time – it has to. I recently produced a 500-run B2 poster. That was a job that I thought would have been comfortably within the sweet spot for digital, but litho came out cheaper. That highlights the overall benefits to a buyer of the competition between processes and vendors.

A large sheet means more options and more efficient production. It offers a lot of potential. Who knows what is going to come out next? Just as B2 digital has enabled more possibilities, a B1 digital will also do the same. A new world of work is opened up by a bigger sheet, whether that is an HP Indigo, Screen, Fuji, Landa’s Nanography or another manufacturer or technology.

Ultimately, though, there is nothing wrong with B3 digital, or B2 digital, or, if it comes, B1 digital. No particular press format is right. Different formats address different markets.

Francis Atterbury, has over 25 years’ print-production experience, having worked with most processes from letterpress to digital and reproduction technology from cameras through scanners to digital origination