The Rochester-based company will install radio frequency identification (RFID) microchips and sensors on each of the Mainstream blankets to relay real-time information on performance and lifespan.

OBU chief executive Peter Milton said: The RFID tags are revolutionary because they can work with the nickel cylinders. They will be able to tell how many impressions you get from the blanket on a certain paper, and whether you have to wash up more times using different papers.

Milton, a former Adscene production director, said that real-time information would reduce administration costs and boost production efficiency.

Trafford Park Printers managing director Jacques de Wit said the new system would help the company to manage the cost of consumables.

The blankets on our Goss presses are replaced every eight or nine weeks even if one may have been smashed and replaced the week before. This will help with cost management, said de Wit.

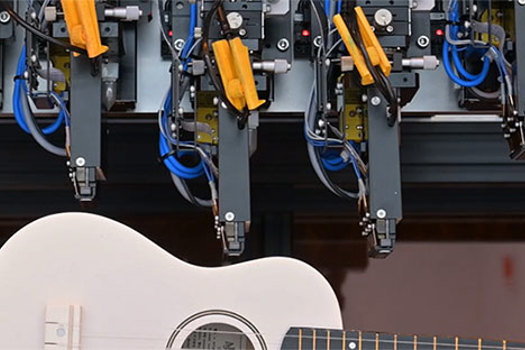

Commissioning tests continue on the two Heidelberg Mainstreams, each of which has 35 printing couples, and full production could start by September.

Story by John Davies

Have your say in the Printweek Poll

Related stories

Latest comments

"Gosh! That’s a huge debt - especially HMRC! It’s a shock that HMRC allowed such an amount to be accumulated."

"Whatever happened to the good old fashioned cash job! At least the banks didn't take 2-3% of each sale. After 30 odd transactions that £100 quid you had has gone."

"It's amazing what can be found on the "web" nowadays!"

Up next...

Turnover boosting wins

FDM in bumper triple contract win

Interim boss already in place

Royal Mail chief executive quits

Prints onto complex objects