Explaining the development of the C16, KBA said that while previous focus for press manufacturers has been on larger, up to 96-page presses, the fact that more than half the global press installations are for 16-page machines, has been ignored.

It claimed that, with shorter runs and more targeted audiences, a lot of print work can be more efficiently carried out on smaller-format presses, such as the C16.

KBA's C16 press is available in a 55,000cph or a 65,000cph model, placing it between the Compacta 215 and 217 in KBA's portfolio.

KBA UK managing director Christian Knapp said that the C16 would also be available at a later date in a more standardised configuration at a lower speed.

He said the C16 was "a brand new platform; it's not a new version of an existing machine. It has been designed with one focus in mind - makereadies. A complete plate change in under 60 seconds makes it faster than many sheetfed machines."

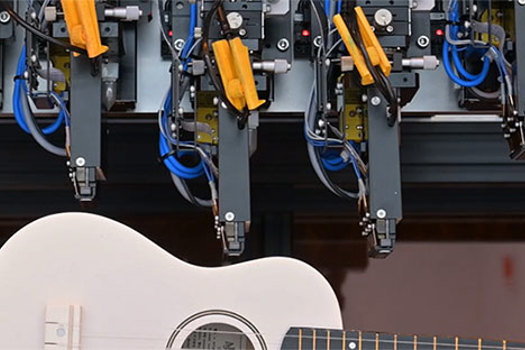

According to KBA, the C16's PlateTronic system enables a complete plate change of any number of plates in less than a minute, while optimised EasyTronic software ensures start-up and run-down operations are quick and minimise waste.

Knapp said the new press would be pitched against sheetfed machines, particularly as replacements for multiple B1 long perfectors, as well as replacements for existing 16pp web presses for which "there was previously no avenue for a cost-effective replacement".

It includes a number of other features to increase automation, including RollerTronic automatic roller locks, borrowed from KBA's newspaper presses. These reduce maintenance and running costs, enabling adjustment of inking rollers in less than two minutes from the console.

The press also boasts and automatically convertible P3 folder, with one quarterfold running up to 65,000cph, as well as dedicated AC drives for each of the couples in each printing unit to make the operation more energy efficient and to generate, therefore minimising wear and tear.

The C16 is available now, with orders taking around five months to complete. Knapp said the press will be on offer at Ipex, but will not be present at the show.

The first customer for the C16 has been revealed as German commercial print company LN Schaffrath, which will install a 65,000cph model in August of this year.