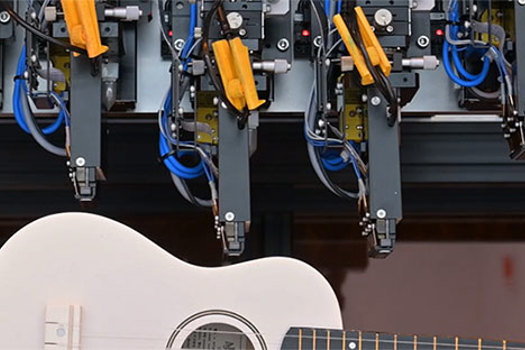

Using piezo printheads from Ricoh, Objet enables manufacturers and designers to build prototypes by jetting layers of liquid photopolymeric acrylic-based materials.

The range of nearly 70 liquids allows for the simulation of a wide range of different product characteristics, such as different levels of rigidity and flexibility.

Objet systems are even able to mix different liquids in one 3D print, creating even more possibilities. The company already produces custom-fit hearing aids and dental implants.

Other applications in the field of rapid manufacturing were now limited only by the need to develop new and innovative materials, according to Objet.

Tweet

Have your say in the Printweek Poll

Related stories

Latest comments

"Gosh! That’s a huge debt - especially HMRC! It’s a shock that HMRC allowed such an amount to be accumulated."

"Whatever happened to the good old fashioned cash job! At least the banks didn't take 2-3% of each sale. After 30 odd transactions that £100 quid you had has gone."

"It's amazing what can be found on the "web" nowadays!"

Up next...

Turnover boosting wins

FDM in bumper triple contract win

Interim boss already in place

Royal Mail chief executive quits

Prints onto complex objects