Lynhurst Press has made further investment in new kit, bringing its spend in the past year to over 2m.

A Duplo DT10 60 collator has been added, providing a facility that collates, folds and four-edge stitches with 20 positions.

"In the past three years we have gone from having Rotaprint and Heidelbergs to CTP and Komori," said managing director Alex Samuels.

He said Lynhursts business boiled down to producing everything that appears in books, such as inserts and reader subscription forms.

The choice for companies in the printing industry these days came down to "invest or die", according to Samuels.

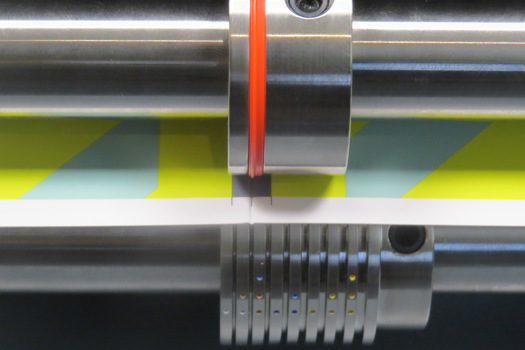

Further spending includes a B2 Komori Sprint perfecting press with high-back delivery, which was one of the first in the UK.

Romford-based Lynhurst employs 30 staff and has sales of around 3m.

Have your say in the Printweek Poll

Related stories

Latest comments

"Gosh! That’s a huge debt - especially HMRC! It’s a shock that HMRC allowed such an amount to be accumulated."

"Whatever happened to the good old fashioned cash job! At least the banks didn't take 2-3% of each sale. After 30 odd transactions that £100 quid you had has gone."

"It's amazing what can be found on the "web" nowadays!"

Up next...

Business is 'on solid ground'

PCP chairman takes majority stake

Ease of use highlighted

Tech-ni-Fold targets folder performance with new scoring device

Launch due next year

Norske Skog Skogn mill to enter book paper market

Winners announced