After having to skip a cycle due to the Covid-19 pandemic, continuous-feed inkjet sector trade show Hunkeler Innovationdays returned to its usual venue of Messe Luzern in the beautiful Swiss city at the end of February.

With visitor numbers of 6,700 an increase on the four-day show’s last outing in 2019, it was a little like going back in time to a pre-pandemic exhibition, which was reassuring to see after some of the lower key returns for various other industry events over the past 18 months or so.

Stefan Hunkeler, chairman of the board of directors at the Swiss paper processing specialist that arranges the event, described the show as “a complete success”. He said there were 100 exhibiting companies and, roughly in terms of visitors, 20% came from Switzerland, 20% from Germany, 40% from the rest of Europe, and 20% from overseas.

“We have been focusing on high-performance digital printing for years. In the meantime, there is no comparable event that shows such practice-oriented and workflow-spanning solutions in this segment,” he said.

“The many experts and specialists on site create a unique atmosphere. Everything is reduced to solutions and advice – with a minimum of promotion. The fair is clearly laid out and offers enough space for discussions.”

While the format and feel of the show had barely changed since 2019, some of the technology on offer had moved forward considerably. Automation was already a key trend in 2019, but this year – running under the motto ‘Next Level Automation’ – it was easily the biggest topic of conversation, particularly the way in which automation, including workflow, increasingly efficient and flexible integrated high-speed finishing, robotics, handling systems, and the general reduction of touchpoints, has become more crucial than ever before.

Covid, as well as the numerous other economic, political and supply chain challenges of the past few years, has changed the shape of many print businesses, which need to be at least as productive as they were before, but often with fewer staff.

“The market is increasingly demanding automated solutions. There were strong trends that have been emerging for some time: inkjet is becoming suitable for mass production. On-demand book production is on everyone’s lips, and Hunkeler offers with the new Book Sorting Module a first solution in the Smart Logistics Solutions brand,” said Hunkeler.

“The mailing sector is registering increasing interest in high-volume digital printing. The cut-sheet sector will increase in the B2 format. It remains exciting and we at Hunkeler are fully involved. Whereas four years ago it was all about automating individual machines and systems, today we are ready to automate entire processes.”

Tracey Koziol, executive vice-president of Global Offering Solutions and chief product officer at Xerox, said the manufacturer is moving its own suite of automation options forward with a particular focus on press uptime.

“We’ve had very strong pull on CareAR. With that, the thing is controlling everyone’s imagination of what you can do with it. The ‘Assist’ part, with the augmented reality, is very simple for customers and for us to implement, and I think that piece is good. We’ve got quite a few customers and partners now trying it for themselves.”

Friedheim International is the UK distributor for Hunkeler as well as other exhibitors, including Kama, Komfi and Scodix. It flew 90 of its customers over to the event, according to managing director Mark Bristow.

“We have such a good relationship with our customers and generally know them very well, so we know the background of all of our customers who came, and we ideally know what they’re trying to achieve. You can clarify their thinking at something like a show, which advances, develops and takes projects further forwards.

“Especially with the four-year gap, instead of the usual two, even more developments have taken place in the market, so more than ever before, customers were coming to see what has changed and what is coming out in the future. This is also very relevant to help advance people’s thinking about where they’re going and what their plans are,” Bristow said.

“To help support and develop our customers’ businesses, it’s very important for us to be able to demonstrate and show to them where the market is going and where the potential is, and by far the best way is to stand in front of a machine and see it run with product going through it.”

What was being discussed as a possibility in 2019 is in many cases now a reality, although inkjet still has a long way to go in terms of market penetration.

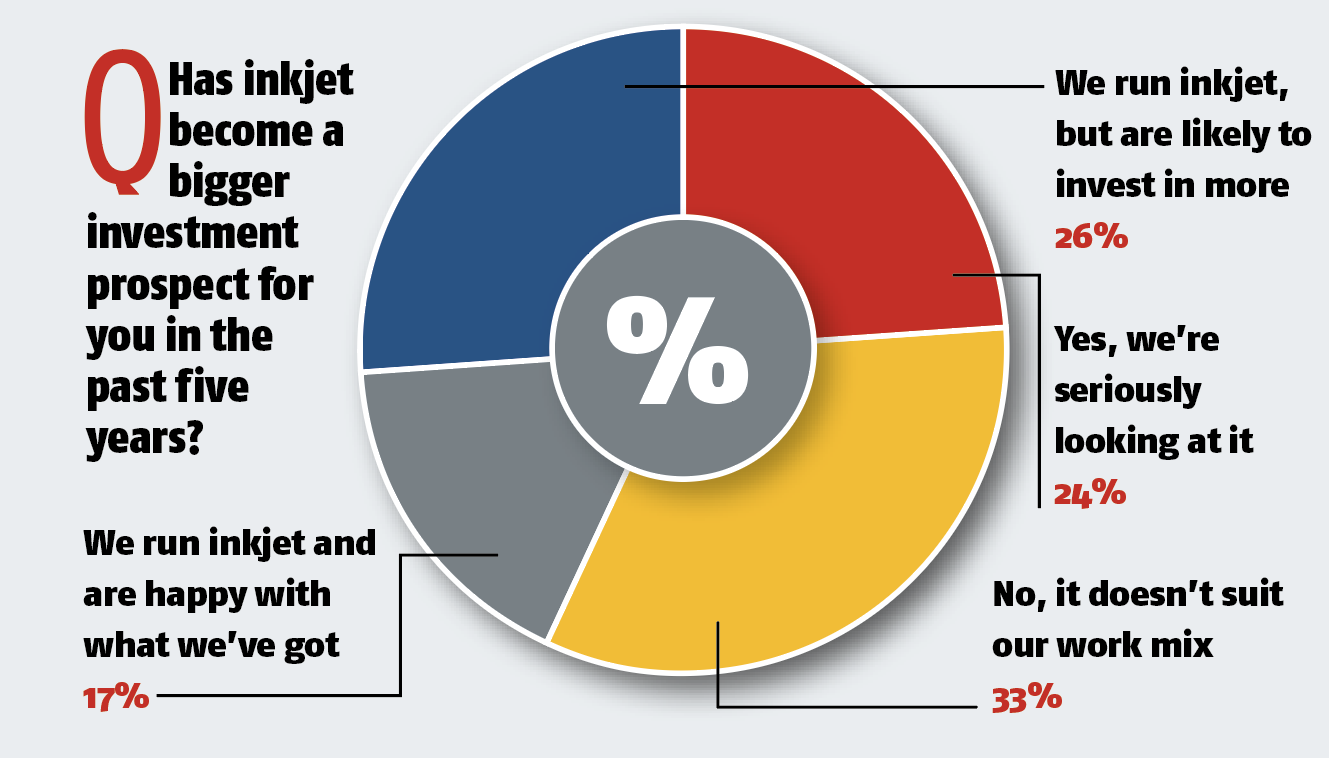

The appetite is clearly growing, though – a recent Printweek poll that asked “Has inkjet become a bigger investment prospect for you in the past five years?” found that while one-third (33%) said it did not suit their work mix, the remainder were either now seriously looking at it (24%) or already running inkjet and likely to invest in more (26%), or happy with what they’ve got (17%).

This trend was clear at Hunkeler Innovationdays. Where the show used to focus on monochrome transactional print and low-level direct mail, it is now moving further away from that, becoming a more specialist general inkjet show, with more commercial jobs running live than ever before.

The findings from a recent poll on Printweek.com

The findings from a recent poll on Printweek.com

Some visitors were completely new not just to inkjet, but to digital technology altogether, according to Eef de Ridder, vice-president of Graphic Communications at Ricoh Europe, who felt the current economic climate was helping to speed the transition to inkjet.

“The cost of labour is getting increasingly high, as are energy and paper costs. For some companies, there is a do-or-die challenge in the coming years to be able to offset the risks of that by creating new business areas and working more efficiently and effectively,” De Ridder said.

“Toner technology is still very important for us, and we will continue to invest in it, but you reach a certain limit if you look at productivity. We cannot get much better on quality, and the costs are already at a certain level that cannot go down. But if you look at inkjet, we haven’t reached the boundaries of productivity, quality or media flexibility, and because of the economies of scale, cost levels can still come down.”

Annette Friskopp, global head and general manager at HP PageWide Industrial, felt the drive towards inkjet was also down to the current challenges in the job market, with many skilled offset printers reaching retirement age and much of the younger generation coming through preferring the appeal of digital technologies.

“The learning curve [for offset] is longer than people are willing to stay in their jobs right now, and more than a few customers have told me that it’s not sexy to run an old analogue machine. Design matters, and the fact that our PageWide Advantage 2200 looks so attractive makes it exciting, and is attracting young people to take these jobs and be associated with this equipment.”

The overarching feeling from the exhibitors and industry analysts Printweek spoke to at the event is that the biggest leaps forward in the technology since 2019 have been in the press drying systems that are helping to facilitate high quality at very high speed – and the extensive work done to make those as sustainable as possible – and the increased ability for continuous-feed inkjet presses to successfully run a much wider variety of substrates, including offset-coated stocks.

However, inkjet treated media has also come down in price – still more expensive than offset-coated media, but closer in price than it was four years ago.

The difference in the quality of print produced by offset and inkjet presses is also becoming ever closer, with multiple vendors at Hunkeler claiming that the quality is now comparable.

The UK printers who travelled to Lucerne were largely impressed with what they saw. Tim Smith, CEO at Seaham mailing house CustomerKNECT, felt the event had “an exciting range of innovation and R&D on display”.

“While the usual heavy metal kit was well presented and visually impressive, the highlight for me was the advancement of programmable finishing equipment and MIS software. Market disruption and interest rates add pressure to a capital-intensive sector, so niche and specialism is the way forwards.”

Glasgow book printer Bell & Bain’s chairman, Stephen Docherty, and managing director Karen Baillie had travelled to the event to scope the market, having invested in smart binding equipment at the previous Hunkeler show they visited.

They were particularly keen to hear from manufacturers “about how they are reducing the power usage of their machines, as digital takes a lot of juice – it’s just constant with heating and drying and blowing”. They were also pleased to see the advances on inkjet press compatibility with offset-coated stocks.

Overall, Hunkeler Innovationdays was a major success, and served to highlight the exciting future of inkjet, as well as the rising use of automation and AI in the sector.

The show will now return to its biennial cycle, with the 2025 event set to take place again at Messe Luzern on 24-27 February. Before that, though, the first in-person Drupa since 2016 will take place next year. And while there was no shortage of launches and developments in Lucerne, there is a good chance that many suppliers will be waiting for the Düsseldorf behemoth to show their full hand.

Ralf Schlözer: Human interaction keeps industry alive

It was good to be at Hunkeler Innovationdays again, with ‘Next Level Automation’ as its motto. This certainly held true. Fifty print application lines were shown live, with many inline or highly integrated solutions. Hunkeler launched several interesting pieces of equipment, including a B2 cut-sheet finisher moving into a new level of productivity. The event is always a great opportunity to showcase new printers as well. Canon introduced a revamped ProStream, with improvements mainly in substrate handling for heavier papers, but the improvements in setup, energy consumption, print quality and footprint will be important for many users.

Equally, the first European showing of the HP PageWide Advantage 2200 brought limited changes on the spec sheet, but lots of interesting features in automation, an impressively small footprint and innovative engine design. Yet, first and foremost, Innovationdays is a place to meet and talk to other people. The conversations I had offered me incredible insights, and it was great fun to catch up with so many people again. The live trade show is back again!

For me it was the tenth visit to Hunkeler Innovationdays, with my first visit dating back to 2003. The 2023 show confirmed the ongoing importance of live trade shows, with at least as many visitors as before the pandemic. The ‘Next Level Automation’ for print production will mean less human staffing on the production floor. However, the event also confirmed that human interaction is what keeps our industry alive by exchanging ideas, getting information and giving feedback.

But I believe we will see more progress, especially with printers, at Drupa 2024 and I felt that vendors played it safe at Hunkeler Innovationdays, showing working production lines rather than any technology jumps. I would say that inkjet on coated paper is already here, but that the existing limitations tend to get less and less.

Ralf Schlözer is an independent print analyst at digitalprintexpert.de

On the stands at Hunkeler Innovationdays 2023

Bowe Systec showed its Fusion Speed 30K inserting system – the fastest and most efficient model in the Fusion series with an output of up to 30,000 envelopes per hour. It was being demonstrated in combination with the new Boxit system for automatic filling of postal trays.

Canon Europe launched the ProStream 3000 high-speed, web-fed inkjet press, which is pitched as delivering consistent offset print quality. Hans Schmidbauer, director of marketing at Canon EMEA, said the specific focus was “to increase productivity on the higher paper weight – a requirement that we have seen from our customers, especially in commercial print environments, where they print postcards, direct mail, calendars – papers that go beyond 160gsm”. He added the machine can print “66% faster on papers up to 200gsm, and beyond 200gsm we are offering a doubling of the productivity on the ProStream 1000”.

Fujifilm took a stand following the company’s acquisition of inkjet integrator Unigraphica last year. It used the opportunity to promote the virtues of the deal to visitors.

Horizon showcased products connected to its iCE LiNK cloud-based machine and workflow management system, including a smart binding system offering dynamic hardcover book block and softcover book production. The roll-to-book system featured its ESF-1000 end sheet feeder, GF-500 gauze feeder, and the HT-300 three-way trimmer.

HP unveiled a raft of enhancements to its PageWide Advantage 2200 press, which it showed for the first time in Europe. The machine now prints in quality mode at full 152m/min speed.

Hunkeler introduced the new Starbook Plowfolder book solution as part of its Digital Web Finishing brand. Features include faster, automated quick changeover, and higher productivity. It also showed the new Sheet Cutter in its DocuTrim product that allows

users to process sheets up to the size of B2-plus.

Kodak showcased the Prosper Ultra 520 inkjet web press for the first time in Europe. The machine takes full advantage of the manufacturer’s Ultrastream continuous inkjet technology. Phil Walsh, vice-president sales, digital press and inkjet products, said the press, which has been touted by Kodak as offering “outstanding” offset quality print at high speeds, could “run any paper – coated, uncoated, silk, gloss – no problem”.

Muller Martini presented a world-first with its highly automated Prinova Digital saddle-stitcher.

Plockmatic Group launched the SC6000 – a larger-format version of its digital die-cutting system, with an expanded size capability of 340x710mm allowing it to handle longer printed substrates. Ray Hillhouse, vice-president of sales and marketing at Plockmatic Group Offline Business Unit, highlighted “lots of nice features that make it easy to use,

including a box-making programme” with the bundled software from Intec.

Ricoh showed its Pro VC70000e continuous-feed inkjet press in public for the first time. The machine is an upgraded, automated version of its VC70000 high-speed inkjet press.

Scodix showcased its Ultra 6000 Press powered by Smart High Definition for the first time in Europe. Its focus at the show was on the digital embellishment of offset B1 and B2 sheet formats. Mark Nixon, executive vice-president global sales and marketing at Scodix, was highlighting its digital embellishment capabilities for packaging applications and book publishing. “The second biggest foil market in the world is books and they all do it in an old way, with dies,” he said.

Xerox showcased its end-to-end Production Eco System, from feeding and finishing to its digital printers Baltoro and Iridesse. Its booth also featured its automation workflows, the new FreeFlow Vision with Predictive Analytics, and CareAR Assist Service Management Software.