The move follows more than a decade of research at the InnovationLab located in the town of Heidelberg. This venture came about through the German government’s ‘Leading-Edge Cluster Competition’ and the press manufacturer is one of the shareholders in the lab, alongside BASF, SAP, Heidelberg University and the Karlsruhe Institute of Technology.

Heidelberg said that together with InnovationLab it had ambitions to become a leading global player in this specialist field, and cited “huge economic potential for printed sensors” as a potential billion-euro sales market over the next ten years.

Heidelberg CEO Rainer Hundsdörfer commented: “Embarking on the development and industrial production of printed and organic electronics represents a milestone for Heidelberg and for Germany as an industrial player.

“As we see it, our involvement in this production of high-tech sensors opens up the potential for growth in the two- to three-digit million euro range.”

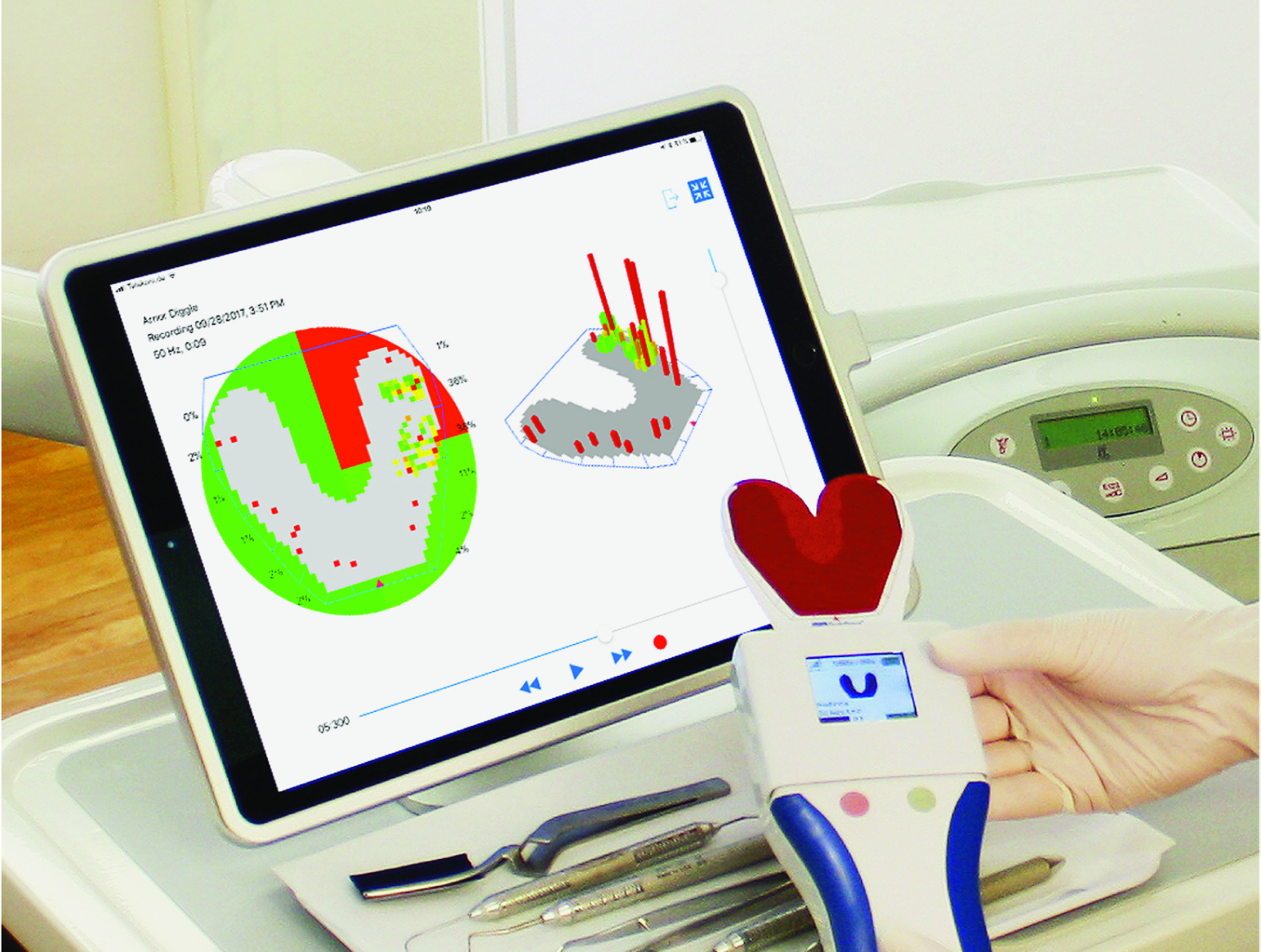

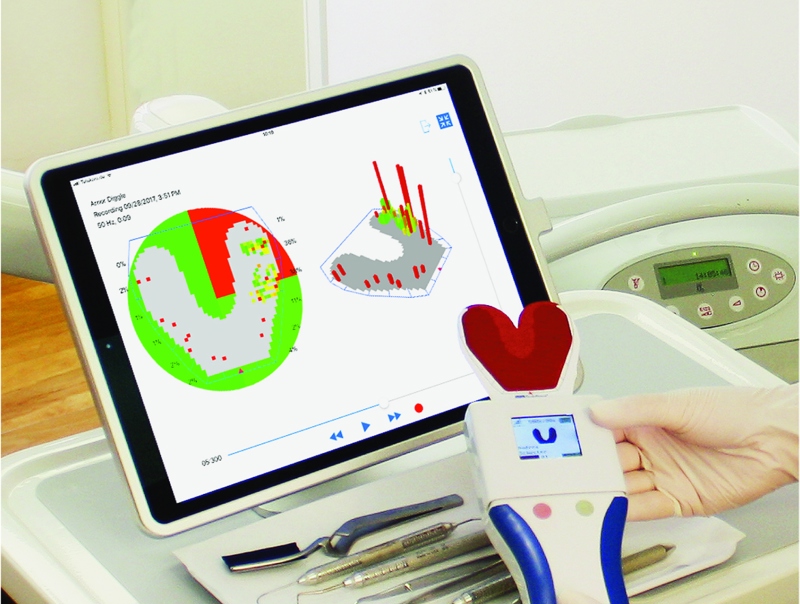

The first product is a printed sensor for use in dentistry (pictured below) to record masticatory pressure during occlusion, when the upper and lower jaws come together.

Other potential markets include healthcare, logistics, retail and automotive.

Other potential markets include healthcare, logistics, retail and automotive.

The production line at Heidelberg’s Wiesloch-Walldorf site involves screen and flexographic printing processes on a Gallus RCS platform, operating in a cleanroom environment.

Each square metre of the printed film is equipped with up to a million sensors able to register “the smallest changes in pressure, temperature or humidity” and report them to a computer.

The entire sensor is printed in a single pass – with all the conductor paths, sensors and the interface to digital terminal devices, Heidelberg said.

It’s a further new area of business for the group following its move into consumer products two years ago with the Wallbox charging station. This business area has since grown to the point where it could be spun off.

A Heidelberg spokesperson said the manufacturer was now “one of the major suppliers in this area” with over 150,000 supplied charging cables and more than 30,000 manufactured OEM wall boxes.

“Since June 2018, we have also been offering our own Wallbox Home Eco, which has already been delivered 5,000 times, to private customers. In line with our focus, we are planning to spin off this area in order to be able to develop it further independently,” the spokesperson said.

In April the Wallbox Home Eco charging system became available in France, Great Britain, Italy, Holland, Austria, Switzerland, and Spain.