DRYING, LAMINATING & COATING

Air Motion Systems Hall 14, B71

Air Motion Systems (AMS) will be launching a new LED curing module based on a uniform blend of wide-spectrum UV and LED wavelengths at equivalent power levels – the first of its kind, the company said. MultiWave LED-UV has been designed for compatibility with many existing UV photo initiator packages, including low-migration formulas. The development means that the ink prices for LED curing can now be similar to those of existing high quality UV inks, according to AMS. Chief executive Steve Metcalf described it as “a true industry first”. The company will also introduce a new low-profile LED module, called the XD Series, for conversion of space-constrained machines to LED printing. It is intended for use with 520mm-format machines with low-pile designs. It will also enable small-format presses to offer ‘offset-on-demand’ LED printing, including instant drying and the ability to readily print on many papers and synthetic materials, said AMS.

Argos Solutions Hall 8b, C9

Belgian firm Argos Solutions has promised that it will unveil a new selective-UV coating print engine. The company is keeping tight-lipped on details but the machine is likely to be based around the same technology as the MK3 launched in 2014 at Ipex. The MK3 can apply up to 10 layers of coating to create effects up to 1.8mm thick. It has an adjustable feed table and can handle items up to 10mm in depth.

Autobond Hall 11, A23

UK manufacturer Autobond will have four laminators and two spot UV varnishers on its booth, including the first showing for an all-singing, all-dancing B1 laminator. The single- or double-sided device can run inline with an inkjet spot UV varnisher, and hot foiling, at 60m/min – the equivalent of 3,600sph B1 format, or 8,000sph in B2. “Every book manufacturer in the world will be beating a path to our door,” says managing director John Gilmore.

CyanX Hall 12, B5-2

UK pressroom consumables business CyanX will be unveiling X-presser, a pressing station for users of its eco-seal tamper-evident self-seal product. The company said X-presser is a compact unit designed for the smaller print companies that works inline with existing finishing equipment, applying the final pressing stage to the eco-seal process after folding. The hardened steel rollers ‘crush’ the mailer as it exits the folder, causing the molecules of the eco-seal to bond together, something that standard folding machines are unable to do.

IST Metz Hall 2, B10

Germany-based UV systems specialist IST Metz, represented in the UK by IST (UK), will be demonstrating its latest UV curing systems for printed packaging and commercial printing with an LED-UV system on a Heidelberg Speedmaster XL 75 (UV-Anicolor) running demonstrations on stand. Chris Schofield, IST (UK) joint managing director, said: “I’m expecting a lively show, with good UK attendance. I expect LE-UV and LED retrofits to be a major topic, as well as our new technology.” The company’s focus will be on its hot-swappable HYcure product concept for sheetfed, web-fed and narrow-web printing. IST Metz said it equips its UV units in such a way that they can be switched to operate either with UV lamps or with UV LEDs.

Lasx Hall 11, E17

Lasx will be showing its new CartonsinMinutes technology, which incorporates a laser cutter with an inline creasing system. Printed boards can be fed to the creaser, which then passes them on to the laser for automated cutting, and then passed to a new robotic stacker or to a folder-gluer for boxmaking. The system is all digital, reading barcodes for creasing and cutting instructions, and can produce one-offs as well as short runs.

Technotrans Hall 2, A4

Press peripherals specialist Technotrans is exhibiting under the banner ‘Partner in Print’ and will emphasise the suitability of its products for all print processes. For 2016, the company will be putting its cooling systems for LE-UV and LED-UV curing kit in the spotlight. It will be showing two brand new energy-efficient cooling systems: the power-controlled alpha.c eco, which is suitable for small and medium-sized formats, and the beta.c blue system, designed for medium and large presses. Both offer adjustable chilling on the fly. These will be shown along with the manufacturer’s alcosmart AZR alcohol dosing system. The company also promises to provide stand visitors with a glimpse of future technology, specifically the ability to use onsite or remote control service support and the smart data network for ink batch management.

FOLDERS/FOLDER-GLUERS

B&R Moll Hall 6, A39

B&R Moll will be launching a compact inline folder-gluer designed to give digital and commercial printers fast, flexible performance for complex packaging products, including cartons, pillow packs, room key sleeves and presentation folders. The digi-mollPak incorporates many proven folding and feeding mechanisms, according to B&R Moll, including an open-format system that facilitates quick changeovers between jobs and a dual-stream capacity to enable multiple feeds. Positive feed control is provided by a bottom friction feeder that offers both continuous feed for regular stock as well as irregularly-shaped materials. A tipper plate with an air blast attachment, movable belts and pans, as well as anti-marking formers maintain the system’s workflow, and the system’s liftgate can be adjusted to allow for a quick job set-up.

Heidelberg Hall 1

Heidelberg will be showing off its latest Stahfolder, the TH/KH 82-P, which has the ability to shingle feed sheets in portrait orientation. Ian Trengrouse, finishing product specialist at Heidelberg UK, explained what the new machine offers printers: “The top of the range Stahlfolder TX 96 increases output by switching to landscape feeding, but it means the folded 16pp sections are imposed differently. Now printers can have the traditional format sections and up to 50% higher output than on the standard TH/KH folders. The key is the feeder and underlapped shingle method that operates throughout the folder.” Heidelberg said the new folder can process 16pp A4 sections at up to 16,000 copies per hour with “minimal” increase in machine speed, thereby avoiding quality issues arising from faster operating speeds. Heidelberg said the TH/KH 82-P is “ideal” for printers running peak performance XL 106 presses and book binders with an annual production of over 40 million sheets. The company added, however, that because it uses existing impositions it can also boost productivity at any bindery.

Herzog & Heymann Hall 6, B40-1/B40-2

Exhibiting as part of the MBO Group, Herzog & Heymann (H&H) will be showing its new Stamina line, a folding carton system with an integrated rotary die-cutter from Bograma. By combining the rotary die-cutting and folder-gluer processes, printers gain the ability to produce ‘nick-less’ folding cartons in one pass, said H&H, and can eliminate the need for additional production steps like refining. The combination also eliminates the need to move work between systems, streamlining and accelerating production processes. The Stamina line also features a camera system that can match pre-printed inserts to the folding carton job, designed to eliminate the possibility of accidental job mixing.

Horizon Hall 6, D5-1/D5-2

Horizon will demonstrate its new AFV-566T6F folder, which features advanced automation that the manufacturer said takes set-up and operation to the next level. Building on Horizon’s proven automated folding technology, the AFV-566T6F includes scoring navigation that can be done automatically through the touchscreen panel, automatic double-sheet detection to minimize waste, improved registration by vacuum belt, quiet operation and easier sheet loading. Optional dynamic folding is also possible to change the fold pattern on-the-fly for variable signatures with minimal or no blank sheets.

IML Hall 14, C75

IML will have a “21-machine presentation” with new devices aimed at packaging, books and stationery applications, including a complete short-run cartoning system targeted at digital printers.

MBO Hall 6, B40-1/B40-2

Under its new ‘Finish First’ slogan the MBO Group will be demonstrating advanced finishing technology and solutions that are designed to help users to improve their efficiency and productivity. A highlight will be the ‘Le Mans’ high-speed folding system, intended for firms with very high outputs.The K8-RS web-fed folding system will make its Drupa debut and demonstrate the speed and versatility of MBO’s modular approach to finishing, the company said.

Masterwork Hall 1, A1-3

Masterwork will show the new modular Diana Smart 55/115 folding carton gluing machine (see ‘must see).

MUST SEE

Masterwork Diana Smart 55/115

The Diana Smart 55/115 is aimed at the mid-production market and offers short set-up times, inline inspection of the entire print image, excellent accessibility due to low side frames on operator and drive side, electronic speed control, and a touchscreen for machine operation, according to Masterwork. Its runs at up to 450m/min and is suited to a variety of applications, including lock-bottom cartons, multi-compartment cartons, miniature cartons, mailing envelopes and record sleeves. On show will be two new versions of the Diana Smart folder-gluers for working widths of 550-1,150mm, including an offline quality inspection system with multiple cameras, to ensure that all added value effects and functions are precisely checked, qualified, and sorted, using a unique combination of cameras, angles and light sources. The Diana Eye 55 fully-automatic sheet inspection system has a working speed of up to 300m/min with a maximum sheet size of 550x500mm and a stock range of 90-650gsm. Masterwork said the system is unique in that it features an adjustable camera light source for multi-process inspection and complex processes such as holograms and foil stamping can be inspected.

The Diana Smart 55/115 is aimed at the mid-production market and offers short set-up times, inline inspection of the entire print image, excellent accessibility due to low side frames on operator and drive side, electronic speed control, and a touchscreen for machine operation, according to Masterwork. Its runs at up to 450m/min and is suited to a variety of applications, including lock-bottom cartons, multi-compartment cartons, miniature cartons, mailing envelopes and record sleeves. On show will be two new versions of the Diana Smart folder-gluers for working widths of 550-1,150mm, including an offline quality inspection system with multiple cameras, to ensure that all added value effects and functions are precisely checked, qualified, and sorted, using a unique combination of cameras, angles and light sources. The Diana Eye 55 fully-automatic sheet inspection system has a working speed of up to 300m/min with a maximum sheet size of 550x500mm and a stock range of 90-650gsm. Masterwork said the system is unique in that it features an adjustable camera light source for multi-process inspection and complex processes such as holograms and foil stamping can be inspected.

BOOKLETMAKERS

Horizon Hall 6, D5-1/D5-2

Horizon will be showing a complete new bookletmaking system, which is designed to combine digitally printed and offset sheets into single documents (see 'must see').

MUST SEE

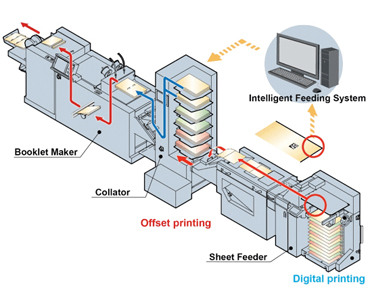

Horizon SPF-200A bookletmaking system

Horizon said the system has been designed to help printers capitalise on the benefits of both digital and offset technologies and is suitable for high-volume variable-content applications. The system takes digital sheets from the HOF-400 digital sheet feeder, while offset printed sheets are taken from the VAC-600 collator. The intelligent feed system uses barcodes to assemble sheets from different bins, which are then converted into a booklet at the SPF-200A bookletmaking system.

Horizon said the system has been designed to help printers capitalise on the benefits of both digital and offset technologies and is suitable for high-volume variable-content applications. The system takes digital sheets from the HOF-400 digital sheet feeder, while offset printed sheets are taken from the VAC-600 collator. The intelligent feed system uses barcodes to assemble sheets from different bins, which are then converted into a booklet at the SPF-200A bookletmaking system.

CUTTERS/PUNCHES

Baumann-Wohlenberg Hall 14, A32

Baumann-Wohlenberg is using Drupa to launch its new concept, Cutting 4.0, which focuses on a state-of-the-art cutting system capable of eliminating bottlenecks and increasing productivity in the finishing process. The concept is built around a BASA automated jogging system connected directly with a high-speed cutter through a logistics system and a multi-ream rack. Equipped with 20 ‘storage spaces’ the BMR is responsible for the job management. As a result, printers can avoid transporting or storing of pre-jogged reams.

Bograma Hall 6, B38

Bograma said it would be presenting new “customer-oriented total solutions that meet the high quality and economic performance requirements in label and packaging printing, job printing and digital printing”. New is the BSR 550 basic rotary die-cutter. Bograma said the BSR 550 basic is designed for users who want to produce short and medium print runs economically and efficiently. It is an offline system suitable for die-cutting, kiss-cutting, creasing, perforating and embossing a wide range of products, such as packaging materials, labels, mailings, presentation folders, etc, from both offset and digital printing. Die-cutting is performed with two magnetic cylinders, and the breakout and delivery unit has been re-designed, meaning that all air nozzles and deflecting pulleys can be inserted and aligned without using tools.

Duplo Hall 6, B61-1/B61-2

Duplo International will use Drupa as the launchpad for a raft of new products the most significant of which is the PFi Di-Cut 300 (see ‘must see’).

MUST SEE

Duplo PFi Di-Cut 300

The Duplo PFi Di-Cut 300 is an on-demand die-cutter that can produce a variety of digital print and packaging products. It can perform multiple cuts, slits, slit score, kiss cuts, perforations and window punches for single or multiple-up pieces, on a wide range of paper stocks at 3,000sph. Duplo said a major benefit is an industry-first X&Y automated registration system. Registration mark smart technology enables the machine to counter image drift. It is operated by a simple touchscreen panel that provides micro adjustments.

The Duplo PFi Di-Cut 300 is an on-demand die-cutter that can produce a variety of digital print and packaging products. It can perform multiple cuts, slits, slit score, kiss cuts, perforations and window punches for single or multiple-up pieces, on a wide range of paper stocks at 3,000sph. Duplo said a major benefit is an industry-first X&Y automated registration system. Registration mark smart technology enables the machine to counter image drift. It is operated by a simple touchscreen panel that provides micro adjustments.

Highcon System Hall 9, C50

Israeli firm Highcon will unveil three new cutting and creasing machines, from entry-level to high-spec. The big draw will be the Highcon Beam, currently in beta testing at Glossop Cartons. The machine is said to be suitable for mid to large folding carton converters, large trade finishers and B1 commercial printers and has a top speed of 5,000sph. The Highcon Pulse offers digital cutting and creasing in a smaller format. The machine, which has a top speed of 2,000sph, is aimed at B2 commercial printers and B2 digital converters.The Highcon Euclid III is said to cater for future growth by opening the door to new opportunities in high-value applications and markets. The machine has a top speed of 1,500sph.

Hunkeler Hall 8a, C20

Hunkeler will introduce its proprietary Dyna-cut technology as part of a book-on-demand solution for variable-format inline book production, converting pre-printed rolls to pre-glued book blocks. Automatic variability of spine length between stacks is possible using the new Dyna-cut function in the CS6-HS Cutter and SD7-II Stacker, which enables dynamic, barcode-driven changes in sheet length. Rolls are processed into four-, six, or eight-page signatures in the PF7 Double Plow Folder, with variable sheet count and page number from one book to the next. The SD7-II double star wheel delivery unit provides integrated book block gluing at speeds of up to 200m/min. Book blocks produced on this solution will in turn be used to demonstrate Hunkeler’s debut of the BD7 Dynamic Book Destacker. The BD7 serves as the interface connecting Hunkeler book block solutions to any perfect binder – making it possible to go from roll to finished perfect-bound book in one end-to-end process, according to Hunkeler.

Masterwork Hall 1, A1-3

Chinese manufacturer Masterwork will mark its debut as a Heidelberg partner with the biggest presence of any of the German press giant’s partners. It will be unveiling a new “peak-performance” 106 die-cutter with blanking facilities that the company said would “deliver maximum productivity at a great price performance ratio”. The new model, the Promatrix 106 CSB, will complement the entry level die-cutter, the Easymatrix, and the professional class for medium to long runs, the Promatrix 106 CS. It runs at up to 8,000sph and handles a maximum sheet size of 760x1,0670mm.

Tecnau Hall 8a, D63

Tecnau is showing for the first time its CutReady finishing system, developed to finish pre-printed rolls into fully trimmed output of variable size, taking output from an HP Indigo WS6800p digital press. The CutReady system consists of an Unwinder 550, Cutter TC 7000 TS, Shingling Table TC 0250 and of the optional Collecting Box TC 0040. Tecnau said it could efficiently produces groups of sheets of variable length at speeds up to 100m/min. CutReady supports a wide range of applications, media types, and paper weights – completing 1-, 2- and 3-up output in standard photo sizes, according to the firm. It delivers layflats for offline finishing, book covers with inline or offline lamination, calendars, canvas and other specialty products, as well as long- sheet applications such as posters and banners.

Polar Hall 1, C3

Polar will be present a range of kit targeted at markets including commercial, digital, label and book printers. Two new products will be shown: a new D115 guillotine and an automated laser die-cutter, the Digicut Pro, to build on the success of the manual Digicut Eco, launched last year. There will also be upgrades to Compucut and the Transomat products. The new Polar D115 is described as “an economic hydraulic cutter for larger formats and an ideal product for digital print shops as well as litho printers” and will be available later this year. The Digicut machines cut, emboss and perforate in one operation and can produce boxes, stationery, folders, lanterns and more.

Zünd Hall 9, C5

Zünd said that High-performance digital cutting solutions and intelligent automation will be the focus of its stand and will be exhibiting under the banner ‘Double your productivity’. The Swiss manufacturer has promised to unveil a brand new “ultra high-performance” digital cutting system and said that the new machine reflected the importance of productivity and efficiency as primary drivers of growth. Zünd has not revealed much in the way of detail about the new cutter but said it could double production throughput with no loss of quality. It features a range of technological innovations as well as superb flexibility in handling the widest possible range of materials, the company said. Product manager, packaging Roman Hasler said: “With the new Zünd cutter, we increase the productivity and efficiency of our customers, thereby strengthening their business, which makes this a completely failsafe investment.” The new cutter will be shown operating with the company’s high-performance Board Handling System for fully automated board loading and unloading.

MULTI-FINISHERS

Duplo Hall 6, B61-1/B61-2

DUplo will be showing the DC-646i, which includes a raft of new features added to the DC-646 slitter-cutter-creaser, including expanded job memory, PDF template generator, and side air feeding to ensure smoother operation. The DC-646 JDF is a nearline integration with the HP Indigo 7900 and 10000 digital presses, the DC-646 can perform automatically a wide range of finishing functions such as cutting, creasing and perforating to turn a sheet into a fully finished document in a single pass. The DC-646i IFS is a marriage of the DC-646i slitter-cutter-creaser with the Integrated Folding System (IFS), which enables seven common fold patterns to be produced with a crack-free finish. New features have also been added to the DC-446, which now has 20% faster processing speed to produce 60 A4 ppm, 20 more programmable creases per document, paper width increased from 320mm to 330.5mm, optional long paper trays (up to 670mm), and twice as many feed belts, giving more consistency when feeding various document sizes.

Hunkeler Hall 8a, C20

Taking centre stage on the stand will be a dynamic newspaper and booklet production solution with fully automatic changeover offering ultimate format flexibility. The system will demonstrate two different roll-fed newspaper applications delivering both broadsheet newspapers up to 140pp with nested sections of variable sheet count as well as tabloid newspapers with dynamic gluing in the spine. The system features unwinding on the UW7, cross-cutting in the CS7, sheet gathering in the DC7 Drum Collator, and parallel and cross-folding in the FC7 Folder and Collator. Hunkeler said it is also possible to mix production of broadsheet and tabloid newspapers, with fully automatic line changeover while the job is in progress. Hunkeler will also release an enhanced WI6 web inspection and tracking system that will be demonstrated on multiple Hunkeler lines throughout the halls. The new design employs compact Contact Image Sensor technology for high-end quality and integrity control, and can be combined with the revamped Hunkeler Site Manager for flexible reporting and tracking at the line, job, document and sheet level. The WI6 will also be shown on an HP PageWide T460 press in Hall 17.

Masterwork Hall 1, A1-3

Masterwork said it would be showing a new model in its Duopress range of multi-function finishers, the Duopress 106 FCSB, which offers six processes in one pass: foil stamping, embossing, die cutting, stripping, blank separation, and product collection. The company said that by combining these processes a user can “dramatically” increase efficiency. The 106 FCSB features improved foil control systems that have been designed to ensure accurate foil feeding and create greater foil saving.

MGI Digital Tehnology Hall 5, D21

MGI Digital Technology will be debuting its new digital enhancement press, the Jetvarnish 3D Evolution, which it said is the first digital sheetfed enhancement press to be scalable from B2 to B1. The eight-colour inkjet builds on the original Jetvarnish 3D, first shown in 2008, but will allow owners to buy a B2 machine and then upgrade to B1 if they need to. The B1-format option can produce digitally embellished images, text, data and brand designs using spot varnish, 3D raised varnish and digitally embossed foil in one pass. There are three available substrate size options: 520x1,200mm, 640x1,200mm and 750x1,200mm. The B2 version can operate at more than 4,000sph, according to MGI, while the B1 can run at 3,000sph. Also on show will be the new AIS SmartScanner sheet registration system, which uses “artificial intelligence” to automatically create varnish and hot foil registration for the management of inkjet heads and each printed sheet.

Scodix Hall 4, D60

Israeli firm Scodix will be unveiling its new B1-format multi-function digital enhancement press, the E106 (see ‘must see’).

MUST SEE

Scodix E106

Scodix said its new B1-format multi-function digital enhancement press, the E106 is ideal for short to medium-length runs that it said were previously not viable for printers in the packaging sector. Scodix said the E106 had “ultra-fast” production speeds of up to 4,000sph to help folding-carton printers and converters differentiate their offerings and boost profit margins. Features include Scodix Sense, Scodix Spot, Scodix Braille, Scodix Digital Embossing, Scodix Variable Data finishes and Scodix Foil all in a single device. The foil system was developed by Compact Foilers, meanwhile Scodix partnered with Mabeg Systems to produce the Scodix E106 paper handling system. The E106 can handle substrates from paperboard to plastic and metalised boards, as well as offset and digital prints and water-based coatings and a wide range of laminated products. Marketing director Lynn Kolevsohn said the E106 will start beta testing after the show and commercial deliveries will start in 2017. “The folding carton market is moving toward mass customisation, shorter print runs and a need for better and new embellishments,” she said. “Current technologies suffer from long set-up times, high cost of die and moulds and little flexibility.”

Scodix said its new B1-format multi-function digital enhancement press, the E106 is ideal for short to medium-length runs that it said were previously not viable for printers in the packaging sector. Scodix said the E106 had “ultra-fast” production speeds of up to 4,000sph to help folding-carton printers and converters differentiate their offerings and boost profit margins. Features include Scodix Sense, Scodix Spot, Scodix Braille, Scodix Digital Embossing, Scodix Variable Data finishes and Scodix Foil all in a single device. The foil system was developed by Compact Foilers, meanwhile Scodix partnered with Mabeg Systems to produce the Scodix E106 paper handling system. The E106 can handle substrates from paperboard to plastic and metalised boards, as well as offset and digital prints and water-based coatings and a wide range of laminated products. Marketing director Lynn Kolevsohn said the E106 will start beta testing after the show and commercial deliveries will start in 2017. “The folding carton market is moving toward mass customisation, shorter print runs and a need for better and new embellishments,” she said. “Current technologies suffer from long set-up times, high cost of die and moulds and little flexibility.”

BINDING/STITCHING

CP Bourg Hall 6, C61

CP Bourg is launching the Bourg Preparation Module (BPM), a modular, scalable sheet preparation unit that enables printers to use inline Bourg binders or bookletmakers without operator intervention. The “easy to use” BPM works in-line with select digital printers and presses, as well as offline, or in dual-mode connected to a Bourg Sheet Feeder (BSF), to create perfect-bound or stitched books and booklets. Jobs can be converted from very large formats of up to 600x370mm to very small formats (down to 139x120mm) in a single pass.

Duplo Hall 6, B61-1/B61-2

Duplo is showing the new iSaddle Pro Duetto Digital System, which combines the DSF-6000 sheet feeder with DSC-10/60i suction tower collator. The 350R Pro Inline Booklet System is a combination of the Duplo DBM-350 bookletmaker and trimmer, the ASM-350 squareback and slitter-cutter-creaser that combines with the Ricoh Pro C7100 series colour printer to create a professional inline booklet system. The DC-350Cr Booklet System integrates the DC-446 DuCreaser with the DBM-350 bookletmaker and trimmer. The system can cut, crease and create booklets all in one pass. The DM Mini Collation System extends the productivity and inline processes of its current DM230V Esper Collator. Operated from a centrally located PC, the system offers inline stacking and banding of unaddressed mail sets to deliver up to 50% higher productivity.

Hohner Hall 14, B32

Hohner is to show for the first time its latest saddle-stitcher the HSB 9.000, which is the successor to the company’s 8.000 model. The new stitcher includes a number of performance enhancements, including higher operating speed, improved ease of use and greater flexibility. It can handle a wide range of formats from small sizes up to A4-plus and also features remote control. Hohner said the most exciting development on the new stitcher was the introduction of horizontal feeders, which “bring a totally new dimension of possibilities” to the new machine. The company is also showing the latest version of its HSB Digi-FS 8, which combines the functions of a conventional saddle-stitcher with those of a digital finisher and a folder-stitcher in an integrated finishing system. The revamped machine benefits from the ability to handle sheets up to 1,250mm in length.

Horizon Hall 6, D5-1/D5-2

Horizon will be showing its newly developed BQ-480 four-clamp perfect binder, which it said features particularly rapid set-up and delivers superior quality. The machine features new automation technology that helps it output up to 800bph of variable thickness products. This is designed to help printers meet the demand for efficient short-run, including ‘book-of-one’ production. The binder also features greater automation through the inclusion of a movable, colour touchscreen including adjustments for roller height, nipping height, and amount of side glue. All of these settings are set automatically according to book thickness for easy set-up. Specially designed to meet the requirements of PUR book binding, the BQ-480 includes a elevator delivery system with a mere 5mm drop for gentle book handlings.

IBIS Hall 5, A23 (Domino)

Appearing on the Domino stand, IBIS Integrated Bindery Systems will be demonstrating its latest high-speed model, the Smart-binder SB-3 ‘Plus HS’ inline with a Domino K630i monochrome digital web press and Kern web cutter. The Smart-binder SB-3 will produce finished booklets at speeds up to 7000bph with constantly varying thickness, both wire stitched and ISG cold-glued. Separately printed covers can be fed automatically, on demand, under bar code control.

Morgana Systems Hall 8b, A66

UK post-press manufacturer Morgana Systems will be showing an enhanced DigiBook 150 entry-level PUR perfect binder, alongside a raft of its other machines. The DigiBook 150 has been upgraded to incorporate some of the features of the higher specification DigiBook 200, including automatic book block clamping and a new glue nozzle system, which has been upgraded to give better control of the spine and side glue application, according to Morgana. Morgana said the DigiBook 150 is ideal for conventional and digital printers who require short runs of PUR-bound books to a professional standard.

Muller Martini Hall 2, A49-1/A49-2

Muller Martini has promised a raft of new releases at the show under its ‘Finishing 4.0’ theme, but is at the moment keeping the details to itself. However, it has said it will be demonstrating how variable magazines and books are produced using an integrated, automated machine line-up consisting of hybrid offset and digital print elements. Hundreds of copies of over 20 different print products will be produced live each day using no fewer than nine connected systems, including a bilingual in-flight magazine, which will be produced sequentially in sets of four copies, with varying page counts, in A4 size using the Presto II Digital saddle-stitcher.

Palamides Hall 6, E5

Palamides will be showing its new layflat binding machine, the Smartliner 240, which is specially designed to use the ‘smartflat’ Hydrosiv water-based binding technology. Palamides said the machine is well suited to photobook manufacturers wanting to produce a book that opens perfectly flat. The binding technique is also said to be more environmentally friendly than more conventional alternatives. It handles A3 and A4 portrait or landscape books, up to 40mm thick.

Renz Hall 6, C60

Renz said it would be presenting new punching and binding systems with a focus on intelligent, high-performing and efficient solutions to increase competitiveness. In particular, the firm is targeting small to medium-sized volumes, traditionally served by manual or partially automated systems. Renz has specifically developed the automatic punch AP 300 Compact for this sector. The machine has an infeed pile capacity of 4,000 sheets and allows for unattended production, increasing both productivity and efficiency without incurring increased labour costs, Renz said.

Smyth/Risetec Hall 6, C38

Smyth will be showing the Smyth Blue, a new large-format sewing machine with an inline folder. The machine can be manually or automatically fed and operates at up to 120cph. It can handle sheet sizes of up to 560x360mm. Meanwhile co-exhibitor Risetec will launch a four-clamp binder with inline end-paper insertion, back-lining and soft cover capabilities. The machine is said to be ideal for short-run, on-demand book production. “It’s an excellent solution for small volumes,” said Steve Giddins of UK distributor Perfect Bindery Solutions. “I don’t think there’s anyone else making this sort of machine.”

Tecnau Hall 8a, D63

Italian manufacturer Tecnau will have a range of new kit on show but will primarily be highlighting how its systems aid the book production sector. On its stand will be a Libra One book finishing line taking output from a Canon Océ ColorStream 6000 Chroma and transforming it into book blocks, and the firm will also be showing a new Libra One model for sheetfed operations, the Libra One CS. The Libra One CS eliminates the need for a manual guillotine and automatically transforms single sheets of up to 330x483mm into pre-glued book blocks. The unit can automatically change from 2-up to 4-up imposition and back with no makeready time, at a constant speed up to 16,000sph.

Watkiss Automation Hall 6, C41

Watkiss is showing its new PowerSquare 160 bookletmaker, which is targeted at mid-volume digital printers. The new machine staples, folds, forms and trims in a single pass and is an open-architecture, complete bookletmaking system for producing square-backed books. It builds on the established PowerSquare brand and uses Watkiss’ patented fold-and-form technology to produce the square spine at the same time as folding. This results in a sharper, better quality finish, according to Watkiss sales director Paul Attew. With JDF/JMF compatibility, the machine will be available as an inline, nearline or offline system.

MAILROOM

KAS Paper Systems Hall 6, A18

Centre of attention on the KAS stand will be its newly launched Mailmaster Eclipse inserting machine (see ‘must see’). Also being shown is the Mailwrap polywrapper, which KAS said had been developed to fill a gap in the market for printers and direct mail companies to upgrade from lower speed equipment without having to invest in high speed polywrappers at much greater cost. It handles widths from CD to A4-plus with a maximum speed of 6,000 packs per hour

MUST SEE

KAS Paper Systems Mailmaster Eclipse

KAS said the Mailmaster Eclipse is designed to be a highly productive system, inserting into C4/C5/DL at 8,000 envelopes per hour. Other features include multiple sheet feeding, even at top speed, semi-automatic job changeover, a secondary channel for feeding prime documents, such as a 7mm-thick booklet from the side insert feeder, Datalog tracking of documents and inserts for 100% closed-loop reporting and mailing integrity.

KAS said the Mailmaster Eclipse is designed to be a highly productive system, inserting into C4/C5/DL at 8,000 envelopes per hour. Other features include multiple sheet feeding, even at top speed, semi-automatic job changeover, a secondary channel for feeding prime documents, such as a 7mm-thick booklet from the side insert feeder, Datalog tracking of documents and inserts for 100% closed-loop reporting and mailing integrity.

MISC

Atlas Hall 12, D55

UK firm Atlas Converting Equipment will present the latest generation of its Titan SR800 Series slitting and rewinding technology, which features improved productivity and greater flexibility. Atlas said that when developing the machine, it focused on achieving significant reductions in machine downtime, including reduced set change times, lower operator intervention and also reduction of waste materials, which add up to “outstanding” productivity gains. The SR800 has a top speed of 700m/min and can handle web widths of 1,350-1,650mm, although other widths can be catered for.

Blumer Hall 14, B40

US-based finishing kit manufacturer Blumer said it would be launching the Bandall Labelbander 24 label banding machine for square-cut products. Details were sparse as this issue went to press but the company said the machine combined Blumer’s expertise in label finishing with Bandall’s banding technology to ensure a “very professional and efficient banding process”.

C&T Matrix Hall 10, B52

C&T Matrix will be using Drupa to demonstrate the very latest matrices and associated products for die-makers, box-makers and print finishers, including the company’s new comprehensive range of cutting plates, ejection rubbers and accessories. The range includes steel cutting plates and a full portfolio of parts used by die-makers, including, ‘carrots’, centre-line blocks and edge protectors.

Horizon Hall 6, D5-1/D5-2

Horizon will be highlighting how a focus on post-press can deliver greater production efficiencies. The company will be showcasing the new compatibility of its machines with HP Indigo presses with a demonstration of a SmartStacker taking output inline from an Indigo 12000 digital press. The set-up will deliver automated cutting, trimming, collating and stacking for faster job turnarounds, according to the Japanese post-press specialist.

Tecnau Hall 8a, D63

Tecnau will unveil a new stacker, the Stacker s25, which has been created with improved gripper technology to provide reliable, damage-free handling of heavy-ink-coverage graphic arts applications, according to Tecnau. The company will also present a revamped version of Tecnau Connect, a central platform to control Tecnau finishing lines, collect data and generate reports, enable remote technical support and perform essential integrity controls. It has announced a new cutter for web widths up to 560mm, the TC 7000 W cutter, which supports a wide range of media, from 50gsm up to 250gsm. As with all products in Tecnau’s TC 7000 series, it can be combined with multiple output solutions, including an offset stacker, a shingling conveyor and various third-party finishing devices. The company will unveil two systems for long sheet cutting and stacking, the new Stacker s28 and High Pile Stacker h10. The Stacker s28 is designed to collect up to 250mm-tall offset stacks of sheets, up to 710mm long, with automatic job separationas calendars, posters and banners. The h10 is aimed at higher-volume users, as it collects high piles up to 700mm-tall on a pallet for easy transport to further finishing. It offers continuous delivery, supporting continuous print operations, and an optional cardboard feeder for job separation.