The new device, a pared-down version of the BN-20, is described as value-packed and perfect for industry professionals looking for a compact, all-round print and cut device.

Less expensive than its £5,349 cousin, at around £4,779 the BN-20A uses a simplified CMYK ink configuration without the metallic or white options of the BN-20. It uses roll media, including poster substrates, PVC and PET films, from 150mm to 515mm wide and 1mm thick and features a high-speed option.

According to the manufacturer, the VersaStudio BN-20A delivers the highest-quality graphics and high-definition images and is aimed at new businesses or those wanting to expand their operations by producing small-scale but high-quality applications such as t-shirt graphics, poster prints, stickers and decals.

The device builds on the company’s experience with the existing BN-20, which has a 10-year track record and the highest number of unit sales of any print and cut device, according to the manufacturer.

“The BN-20A epitomises value for money, delivering high-quality, all-round printing and cutting solutions in one compact device, and we’re excited to demonstrate the brand-new solution at Fespa this year,” said Stephen Davis, marketing director at Roland DG EMEA.

The new BN-20A will be working alongside a raft of other devices on the manufacturer's stand in Hall 5 this week, including Roland DG’s new desktop inkjet VersaUV LEC2-330 and LEC2-640 UV.

The print and cut devices are designed for creating anything from packaging mock-ups, premium labels and signs to POS displays and speciality graphics. Using ECO-EUV5 inks the device can print, cut, die-cut, perforate, varnish and emboss.

The 330 can handle media of 182x762mm with a cutting width of 736mm while the 640 can handle widths of 210x1,625 with a cutting width of 1,600mm. The devices cost £16,999 and £19,999 respectively.

Other devices on display at the Roland DG stand will be the VersaUV LEF2-300 printer, CAMM-1 GR2-640 vinyl cutter, TrueVIS VG2-640 printer-cutter and VF2-640 large-format inkjet printer.

The company will also be showcasing PersBiz, Roland DG’s digital webshop aimed at helping print providers to start selling online and provide personalisation options to consumers.

“At Roland DG, we are dedicated to helping our customers achieve their ambitions with our premium quality solutions, and have been working to bring to market some of our most value-packed products to date,” said Stephen Davis, marketing director, Roland DG EMEA.

“We are proud to be able to showcase the capabilities of our highly versatile machines in-person at Fespa, and explore the latest trends and innovations in the industry.”

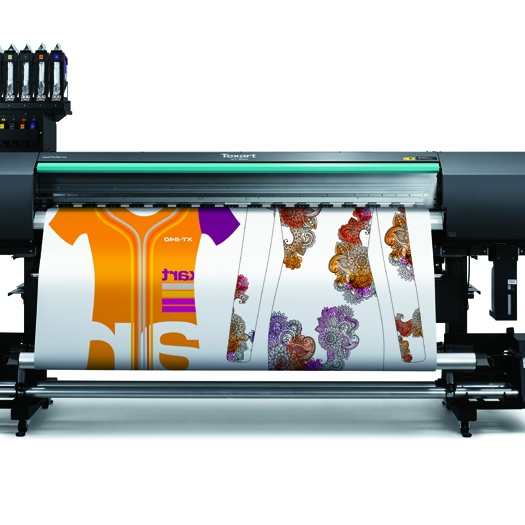

Another new device unveiled by the manufacturer this month, though not showcasing at Fespa, is the Texart XT-640S-F. It is a hybrid direct-to-textile and direct-to-garment printer series aimed at limited-edition, short-run fashion and textile collections.

Available in three bed sizes, the XT-640S-F is targeted at apparel houses and garment manufacturers for short-run fashion, sport and leisure wear, apparel and street wear as well as one-off prototype items for shows. It can handle a wide variety of fabrics, from cotton and cotton-rich blends to white polyester, denim and treated leather.

The Eco Passport by Oeko-tex certified range can print on materials of widths up to 1625mm and a maximum thickness of 200mm. The range comprises the XT-640S-F200 with a bed size of 1,696x2,090mm, the XT-640S-F300 with a bed size of 1,696x3,090mm and the XT-640S-F400, which has a bed size of 1,696x3,818mm.

Paul Willems, director of business development and product management at Roland DG EMEA, said the Texart XT-640S-F was the result of a collaborative project with a number of Italian textile customers and was purpose built for the ‘fashion-drop generation’.

“[It is] a product that will help garment manufacturers to capitalise on the demand for short-run printing and incorporate it into their workflows,” he added.